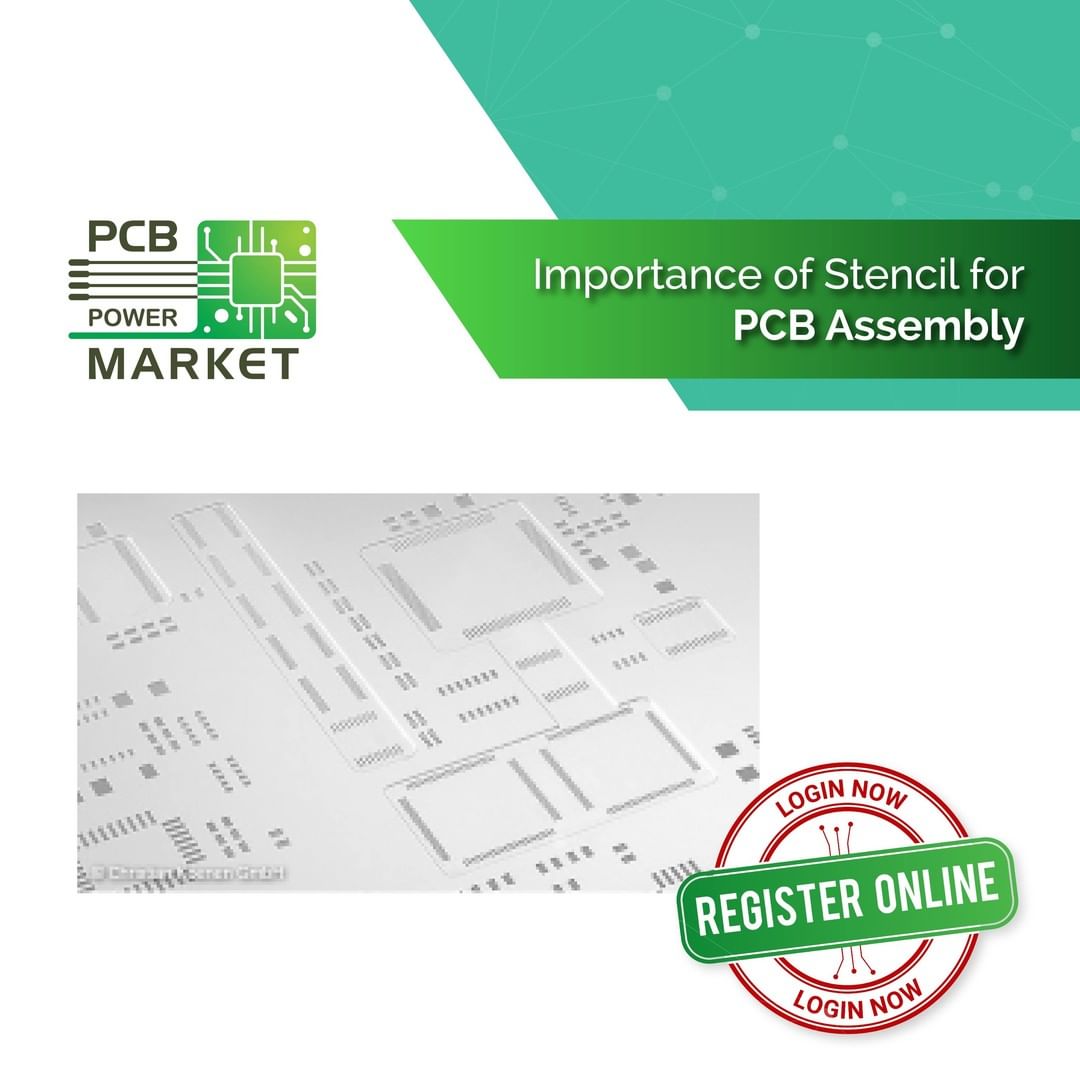

The surface mount assembly process uses a stencil as a gateway to an accurate and repeatable solder paste deposition. A stencil is a thin sheet or foil of brass or stainless steel with a circuit pattern cut into it, matching the positional pattern of surface mount devices (SMD) on the printed circuit board (PCB) for which the stencil is to be used. After accurately positioning and matching the stencil over the PCB, a metal squeegee forces solder paste through the apertures of the stencil to form deposits on the PCB for holding SMDs in place. The solder paste deposits, when passed through the reflow oven, melt and secure the SMDs to the PCB.

https://www.pcbpower.com/blog-detail/importance-of-stencil-for-pcb-assembly

#BePCBWise #MakeInIndia #SupportMakeInIndia #pcbmanufacturers #electronics #pcbelectronics #pcbdesigners #PCBPowerMarket #pcbassembly #pcbmanufacturing #pcbdesign #pcb #printedcircuitboard #electricalengineering #electronicsengineering #pcblayout #ceramicpcb #pcbsoldering #LocalKoVocal #BeVocalForLocal

The surface mount assembly process uses a stencil as a gateway to an accurate and repeatable solder paste deposition. A stencil is a thin sheet or foil of brass or stainless steel with a circuit pattern cut into it, matching the positional pattern of surface mount devices (SMD) on the printed circuit board (PCB) for which the stencil is to be used. After accurately positioning and matching the stencil over the PCB, a metal squeegee forces solder paste through the apertures of the stencil to form deposits on the PCB for holding SMDs in place. The solder paste deposits, when passed through the reflow oven, melt and secure the SMDs to the PCB. https://www.pcbpower.com/blog-detail/importance-of-stencil-for-pcb-assembly #BePCBWise #MakeInIndia #SupportMakeInIndia #pcbmanufacturers #electronics #pcbelectronics #pcbdesigners #PCBPowerMarket #pcbassembly #pcbmanufacturing #pcbdesign #pcb #printedcircuitboard #electricalengineering #electronicsengineering #pcblayout #ceramicpcb #pcbsoldering #LocalKoVocal #BeVocalForLocal