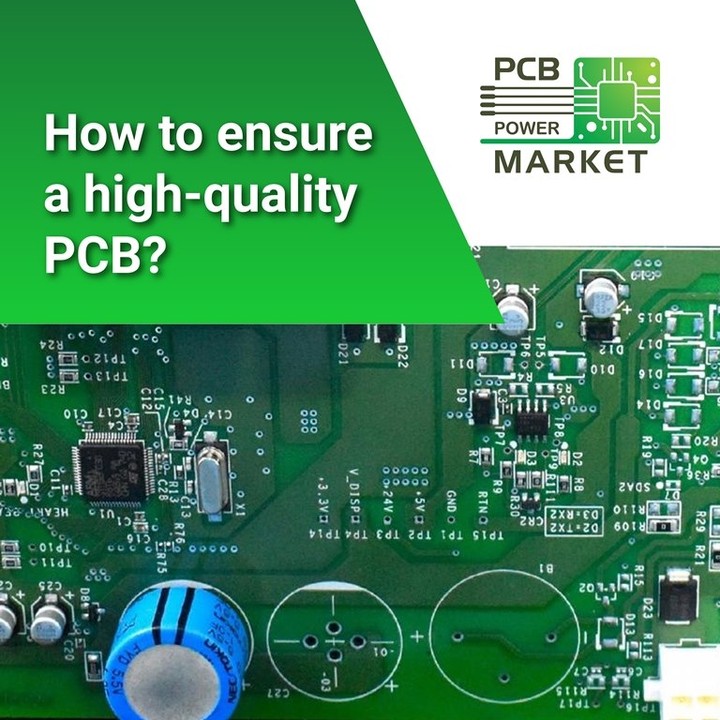

Quality control in the design of PCB is extremely important and you must ensure the following 3 aspects in order to maintain the quality.

Manufacturing Analysis: The technological requirements in the manufacturing of PCB must be strictly adhered to by the project leader and technologist. If the technological requirements are relatively simple, they can be directly listed on design drawings or it can be saved in an additional file in a summarized text format. No matter how much simple the technological requirement might be, it must be explained in a reasonable way in an accurate and clear manner. After the checking of the technological requirement is done it must meet the present production craft level along with being cost-effective and convenient so that subsequent checking, assembly and debugging can be implemented easily.

https://www.pcbpower.com/blog-detail/how-to-ensure-a-high-quality-pcb

#BePCBWise #MakeInIndia #SupportMakeInIndia #pcbmanufacturers #electronics #pcbelectronics #pcbdesigners #PCBPowerMarket #pcbassembly #pcbmanufacturing #pcbdesign #pcb #printedcircuitboard #electricalengineering #electronicsengineering #pcblayout #ceramicpcb #pcbsoldering #LocalKoVocal #BeVocalForLocal

Quality control in the design of PCB is extremely important and you must ensure the following 3 aspects in order to maintain the quality. Manufacturing Analysis: The technological requirements in the manufacturing of PCB must be strictly adhered to by the project leader and technologist. If the technological requirements are relatively simple, they can be directly listed on design drawings or it can be saved in an additional file in a summarized text format. No matter how much simple the technological requirement might be, it must be explained in a reasonable way in an accurate and clear manner. After the checking of the technological requirement is done it must meet the present production craft level along with being cost-effective and convenient so that subsequent checking, assembly and debugging can be implemented easily. https://www.pcbpower.com/blog-detail/how-to-ensure-a-high-quality-pcb #BePCBWise #MakeInIndia #SupportMakeInIndia #pcbmanufacturers #electronics #pcbelectronics #pcbdesigners #PCBPowerMarket #pcbassembly #pcbmanufacturing #pcbdesign #pcb #printedcircuitboard #electricalengineering #electronicsengineering #pcblayout #ceramicpcb #pcbsoldering #LocalKoVocal #BeVocalForLocal