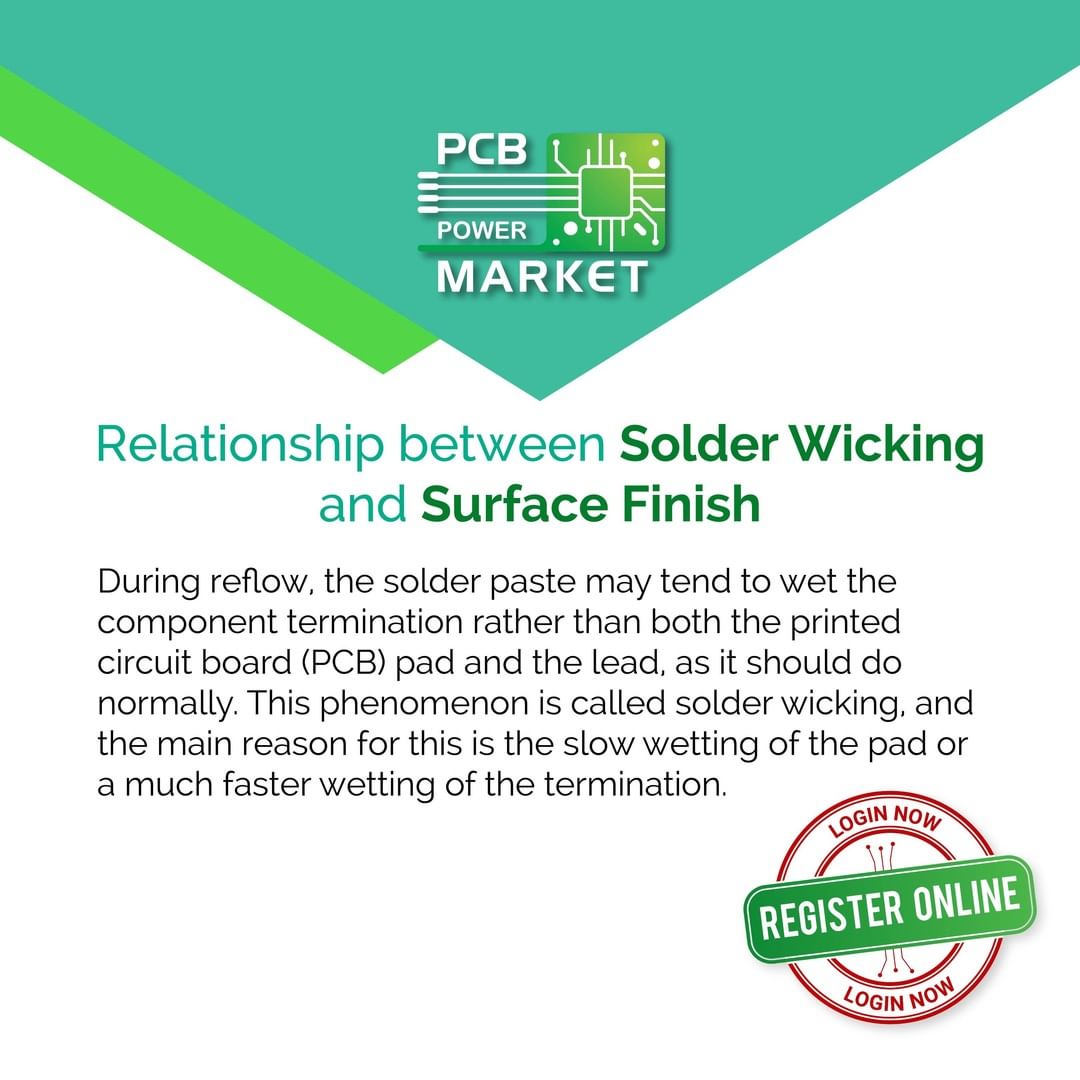

During reflow, the solder paste may tend to wet the component termination rather than both the printed circuit board (PCB) pad and the lead, as it should do normally. This phenomenon is called solder wicking, and the main reason for this is the slow wetting of the pad or a much faster wetting of the termination.

https://www.pcbpower.com/blog-detail/relationship-between-solder-wicking-and-surface-finish

#BePCBWise #MakeInIndia #SupportMakeInIndia #pcbmanufacturers #electronics #pcbelectronics #pcbdesigners #PCBPowerMarket #pcbassembly #pcbmanufacturing #pcbdesign #pcb #printedcircuitboard #electricalengineering #electronicsengineering #pcblayout #ceramicpcb #pcbsoldering #LocalKoVocal #BeVocalForLocal

During reflow, the solder paste may tend to wet the component termination rather than both the printed circuit board (PCB) pad and the lead, as it should do normally. This phenomenon is called solder wicking, and the main reason for this is the slow wetting of the pad or a much faster wetting of the termination. https://www.pcbpower.com/blog-detail/relationship-between-solder-wicking-and-surface-finish #BePCBWise #MakeInIndia #SupportMakeInIndia #pcbmanufacturers #electronics #pcbelectronics #pcbdesigners #PCBPowerMarket #pcbassembly #pcbmanufacturing #pcbdesign #pcb #printedcircuitboard #electricalengineering #electronicsengineering #pcblayout #ceramicpcb #pcbsoldering #LocalKoVocal #BeVocalForLocal

Dec 15, 2020