Designing PCBs with Surface Mount Components

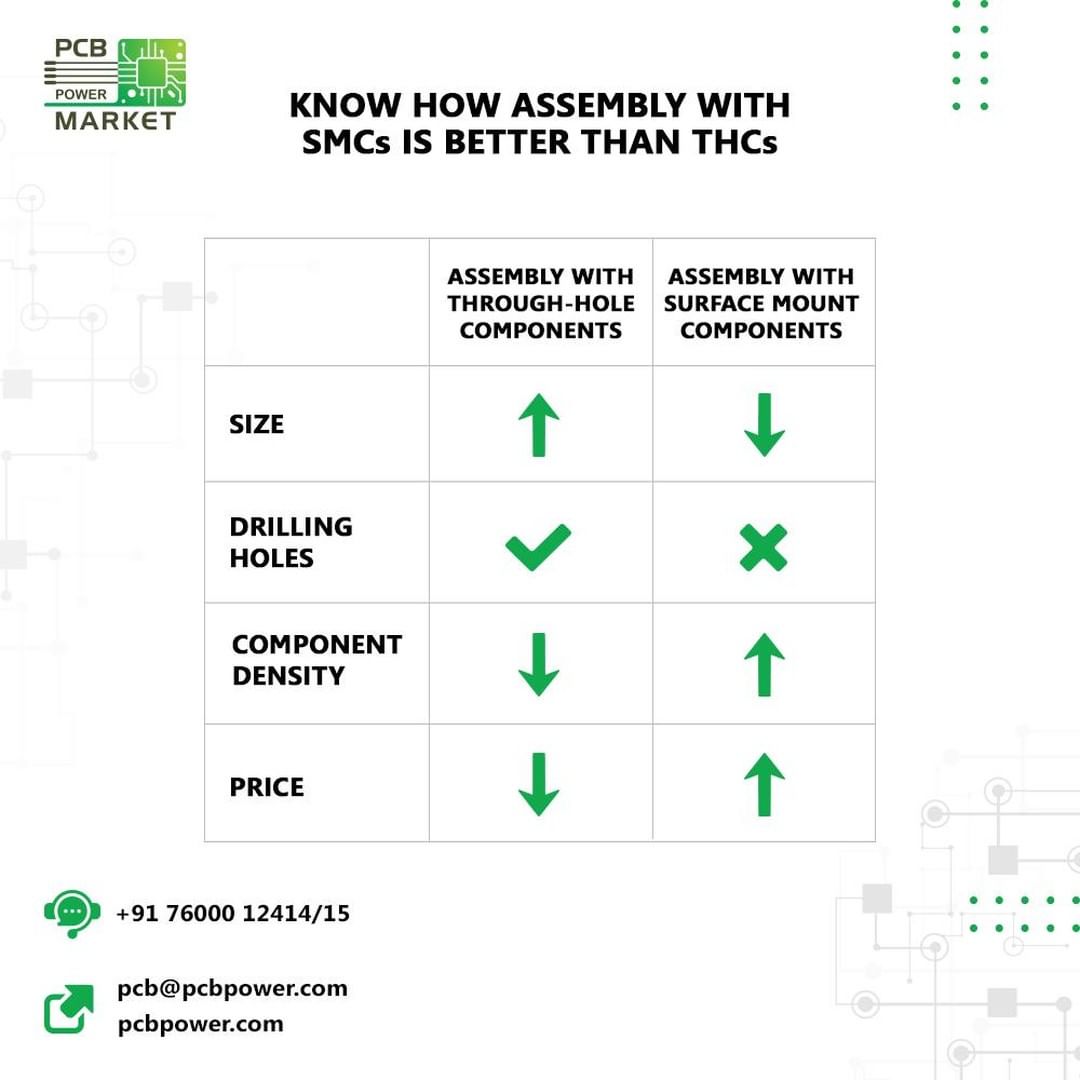

Manufacturers use two types of technologies to make components—Through Hole and Surface Mount—the latter being the latest. Through-hole components have leads that need to pass through the printed circuit board for soldering on the other side. This requires the PCB fabricator to drill holes for all the through-hole components mounted on the board, and this limits the board density, not allowing it go below a certain level.

https://www.pcbpower.com/blog-detail/designing-pcbs-with-surface-mount-components

#BePCBWise #MakeInIndia #SupportMakeInIndia #Aatmnirbhar #pcbmanufacturers #electronics #pcbelectronics #pcbdesigners #PCBPowerMarket #pcbassembly #pcbmanufacturing #pcbdesign #pcb #printedcircuitboard #electricalengineering #electronicsengineering #pcblayout #ceramicpcb #pcbsoldering #LocalKoVocal #BeVocalForLocal

Designing PCBs with Surface Mount Components Manufacturers use two types of technologies to make components—Through Hole and Surface Mount—the latter being the latest. Through-hole components have leads that need to pass through the printed circuit board for soldering on the other side. This requires the PCB fabricator to drill holes for all the through-hole components mounted on the board, and this limits the board density, not allowing it go below a certain level. https://www.pcbpower.com/blog-detail/designing-pcbs-with-surface-mount-components #BePCBWise #MakeInIndia #SupportMakeInIndia #Aatmnirbhar #pcbmanufacturers #electronics #pcbelectronics #pcbdesigners #PCBPowerMarket #pcbassembly #pcbmanufacturing #pcbdesign #pcb #printedcircuitboard #electricalengineering #electronicsengineering #pcblayout #ceramicpcb #pcbsoldering #LocalKoVocal #BeVocalForLocal